Quick Answer: Global T-Shirt Manufacturing Leaders

Have you ever looked at the tag on your favorite tee and wondered, “Where actually made this?” For Australian fashion brands and businesses, understanding the global supply chain is more than just curiosity—it’s a critical business decision.

While the simple answer is often “Asia,” the reality of where t-shirts are manufactured is shifting in 2025. From the cotton fields of India to the high-tech factories of China and the emerging hubs in Vietnam, choosing the right manufacturing origin affects your quality, price, and ethical standing.

This guide breaks down the global landscape of t-shirt production and helps you decide whether to source globally or manufacture locally in Australia.

The Quick Answer: Global T-Shirt Manufacturing Hubs

If you are looking for a quick overview of the global market, here is the breakdown.

Where are t-shirts manufactured globally?

The majority of the world’s t-shirts are manufactured in Asia, which dominates over 80% of global production. As of 2025, the leading countries for t-shirt manufacturing are:

- China: The world’s largest producer, known for advanced technology, speed, and diverse fabric options.

- Bangladesh: The go-to hub for high-volume, budget-friendly production (mass market).

- India: Famous for its high-quality cotton and ethical, organic manufacturing options.

- Vietnam: A rapidly growing choice for premium quality and performance/activewear fabrics.

- Turkey: Preferred by high-end European brands for premium cotton and faster shipping to the West.

For Australian businesses, the choice often comes down to balancing cost (Offshore) vs. speed and control (Local Australian Manufacturers).

Top Countries for T-Shirt Manufacturing (Detailed Breakdown)

When researching where t-shirts are manufactured, it is important to look at the specific strengths of each major player.

1. China: The World’s Largest T-Shirt Producer (32% Global Share)

Why China Dominates T-Shirt Manufacturing:

Production Capacity:

- Output: 15-18 billion garments annually (including 5-6 billion t-shirts)

- Factory scale: Single factories can produce 100,000-500,000 pieces/month

- Technology: Automated cutting (CAD systems), industrial embroidery, screen printing, DTG (Direct-to-Garment)

Cost Advantages:

- Labour: 2−2−3.50/hour (higher than Bangladesh but offset by automation)

- Fabric costs: 1.20−1.20−2.80/kg for cotton jersey (economies of scale)

- Lead time: 25-45 days (sample to bulk production)

Key Manufacturing Hubs:

- Guangdong Province (Guangzhou, Shenzhen): Premium sportswear, technical fabrics

- Zhejiang Province (Ningbo, Wenzhou): Mid-range cotton t-shirts, printing specialization

- Jiangsu Province (Suzhou, Nanjing): Export-oriented factories (Europe/US compliance)

- Fujian Province (Quanzhou, Xiamen): Budget to mid-range, fast fashion

Best For Australian Buyers:

- ✅ Large orders (MOQ typically 500-1,000 pieces/design/colour)

- ✅ Custom designs requiring advanced printing/embroidery

- ✅ Technical fabrics (moisture-wicking, UV protection, anti-microbial)

- ⚠️ Higher MOQs than Bangladesh/India

Typical Pricing for Australian Importers (FOB China):

- Basic cotton tee (180gsm, single colour): 1.80−1.80−2.50 USD

- Premium cotton tee (220gsm, enzyme wash): 3.20−3.20−4.80 USD

- Performance tee (polyester blend, moisture-wicking): 2.80−2.80−4.20 USD

2. Bangladesh: The Budget Manufacturing Powerhouse (18% Global Exports)

Why Bangladesh is the Fastest-Growing T-Shirt Producer:

Cost Competitiveness:

- Labour: 0.50−0.50−0.95/hour (lowest in major manufacturing countries)

- T-shirt production cost: 25-40% lower than China

- Export focus: 80% of production goes to US, Europe, Australia

Production Scale:

- 4,000+ garment factories (employing 4+ million workers)

- Annual exports: $35+ billion USD (60% of national exports)

- Specialization: Basic to mid-range cotton t-shirts, fast fashion

Key Manufacturing Hubs:

- Dhaka: Largest concentration of factories

- Gazipur: Export processing zones (EPZ)

- Chittagong: Port access, faster shipping

Best For Australian Buyers:

- ✅ Budget-conscious brands (maximizing margins)

- ✅ High-volume orders (1,000+ pieces to offset longer lead times)

- ✅ Basic designs (limited complex printing/embroidery)

- ⚠️ Quality variability (factory audits essential)

Ethical Considerations:

- Rana Plaza collapse (2013): Highlighted safety issues

- Improvements since 2015: Accord on Fire and Building Safety, better audits

- Recommendation: Work with BSCI, WRAP, or SA8000 certified factories

Typical Pricing (FOB Bangladesh):

- Basic cotton tee (160-180gsm): 1.20−1.20−1.80 USD

- Standard cotton tee (180-200gsm, screen print 1-2 colours): 1.60−1.60−2.40 USD

3. India: The Cotton T-Shirt Specialist (14% Global Production)

Why India Excels in Cotton T-Shirt Manufacturing:

Natural Advantages:

- World’s largest cotton producer (6+ million tonnes annually)

- Vertical integration: Cotton farms → spinning mills → fabric → garments (single country)

- Quality cotton: Long-staple varieties (ideal for soft, durable tees)

Manufacturing Strengths:

- Tiruppur, Tamil Nadu: Known as “T-Shirt Capital of India” (produces 90% of India’s cotton knitwear)

- Production capacity: 300+ million pieces annually (Tiruppur alone)

- Specialization: 100% cotton tees, organic cotton, GOTS-certified sustainable options

Key Manufacturing Hubs:

- Tiruppur, Tamil Nadu: Cotton knits, dyeing, printing (2,000+ factories)

- Mumbai, Maharashtra: Fashion tees, mid-to-premium segment

- Delhi NCR: Custom design, smaller runs (500-1,000 MOQ)

- Kolkata, West Bengal: Budget production

Best For Australian Buyers:

- ✅ Cotton purists (superior hand-feel, breathability)

- ✅ Sustainable/organic cotton (GOTS certification common)

- ✅ Medium orders (MOQ 300-800 pieces, lower than China)

- ✅ Faster sampling (10-14 days vs 20-30 days China)

Sustainability Edge:

- Organic cotton (India is #1 organic cotton producer globally)

- Fair Trade certification (more common than Bangladesh)

- Water-efficient dyeing (Tiruppur invested $200M+ in zero-discharge systems)

Typical Pricing (FOB India):

- 100% cotton tee (180gsm, combed cotton): 2.00−2.00−2.80 USD

- Organic cotton tee (200gsm, GOTS certified): 3.50−3.50−5.20 USD

- Premium pima cotton (220gsm): 4.80−4.80−6.50 USD

4. Vietnam: The High-Quality & Sustainable Choice (12% Global Exports)

Why Vietnam is Rising as a Premium Manufacturer:

Quality Reputation:

- Skilled workforce: Japanese/Korean management training (precision focus)

- Technical fabrics: Polyester blends, performance wear, activewear

- Lower defect rates: 1-3% vs 5-8% Bangladesh (industry surveys)

-

High quality craftsmanship: Vietnamese manufacturers are distinguished by their expertise in producing intricate, durable, and well-made garments that adhere to high standards of quality and craftsmanship.

Trade Advantages:

- CPTPP member (Comprehensive and Progressive Agreement for Trans-Pacific Partnership)

- Australia-Vietnam FTA: Reduced tariffs (0-5% vs 10-17.5% for non-FTA countries)

- Shorter shipping: 12-18 days to Australia (vs 25-35 days from Bangladesh)

-

Major industry: Vietnam’s textile industry is the third-largest in the world, employing over 2.7 million workers across more than 6,000 factories.

Sustainability Leadership:

- Better Work Programme (ILO partnership, fair labour practices)

- Eco-friendly dyeing: Many factories use OEKO-TEX certified dyes

- Renewable energy: Growing adoption of solar power in factories

-

Sustainable manufacturing practices: Vietnam is emerging as a leader in sustainable T-shirt production, leveraging advanced manufacturing capabilities and eco-friendly practices. Many manufacturers focus on producing eco friendly t shirts using recycled materials and embrace eco-friendly practices with increased compliance to international standards.

Key Manufacturing Hubs:

- Ho Chi Minh City: Largest concentration, export-oriented

- Hanoi: Northern hub, closer to China border (fabric imports)

- Da Nang: Mid-size factories, competitive pricing

Best For Australian Buyers:

- ✅ Quality-conscious brands (retail 30−30−60 price point)

- ✅ Performance/activewear (moisture-wicking, 4-way stretch)

- ✅ Faster turnaround (proximity to Australia advantage)

- ✅ Ethical sourcing (better labour standards reputation)

Typical Pricing (FOB Vietnam):

- Cotton/poly blend (65/35, 180gsm): 2.40−2.40−3.20 USD

- Performance fabric (polyester, moisture-wicking): 3.00−3.00−4.50 USD

- Organic cotton (200gsm): 4.20−4.20−5.80 USD

5. Turkey: Europe’s Premium T-Shirt Hub (6% Global Production)

Why Turkey Serves the Premium Market:

Quality & Speed:

- Geographic advantage: 3-5 days shipping to Europe, 18-22 days to Australia

- European standards: Compliance with EU regulations (easier for global brands)

- Premium fabrics: Supima cotton, organic blends, luxury finishes

Specialization:

- Sustainable production: GOTS, OEKO-TEX, BCI (Better Cotton Initiative) common

- Small-to-medium runs: MOQ as low as 100-300 pieces (ideal for boutique brands)

- Custom finishes: Enzyme wash, garment dye, vintage effects

Key Manufacturing Hubs:

- Istanbul: Fashion-forward designs, premium segment

- Izmir: Large-scale production, export-oriented

- Denizli: Textile mills, fabric-to-garment integration

Best For Australian Buyers:

- ✅ Premium/luxury brands (50−50−120 retail price point)

- ✅ Small boutique orders (lower MOQ tolerance)

- ✅ European aesthetic (fashion-forward designs)

- ⚠️ Higher cost (30-50% more than Asia, offset by quality/speed)

Typical Pricing (FOB Turkey):

- Premium cotton tee (220gsm, combed/ringspun): 4.50−4.50−6.80 USD

- Organic supima cotton (240gsm): 7.20−7.20−9.50 USD

- Luxury finishes (enzyme wash, garment dye): 8.00−8.00−12.00 USD

Comparison Table: Top 5 T-Shirt Manufacturing Countries (2025)

| Country | Global Share | Labour Cost/Hour | Typical FOB Price (Basic Tee) | MOQ (pieces) | Lead Time (days) | Strength | Best For |

|---|---|---|---|---|---|---|---|

| China | 32% | $2.00 – $3.50 | $1.80 – $2.50 | 500 – 1,000 | 25 – 45 | Scale, technology, variety | Large orders, custom designs, technical fabrics |

| Bangladesh | 18% | $0.50 – $0.95 | $1.20 – $1.80 | 1,000 – 3,000 | 35 – 60 | Lowest cost | Budget brands, high volume |

| India | 14% | $1.20 – $2.00 | $2.00 – $2.80 | 300 – 800 | 30 – 50 | Cotton quality, organic | 100% cotton, sustainable |

| Vietnam | 12% | $1.80 – $2.80 | $2.40 – $3.20 | 500 – 1,500 | 25 – 40 | Quality, trade agreements | Performance wear, ethical sourcing |

| Turkey | 6% | $4.00 – $6.00 | $4.50 – $6.80 | 100 – 500 | 20 – 35 | Premium quality, small MOQ | Luxury brands, boutique orders |

Key Takeaways for Australian Buyers:

- Lowest cost: Bangladesh (but factor in quality control costs)

- Best quality-price balance: Vietnam (+ FTA tariff advantage)

- Best for cotton: India (vertical integration, organic options)

- Most flexible MOQ: Turkey (but highest cost)

- Best technology: China (automation, advanced printing)

6-10. Other Notable T-Shirt Manufacturing Countries

| Country | Key Strengths | Typical Use Cases |

|---|---|---|

| Pakistan | Cotton producer, competitive pricing ($1.60 – $2.40 FOB) | Basic cotton tees, large volume |

| Indonesia | Growing capacity, ASEAN trade benefits | Mid-range, Southeast Asia focus |

| Mexico | USMCA agreement (US market), fast shipping | US brands nearshoring |

| Portugal | Premium European production, sustainable | Luxury fashion, ethical brands |

| Sri Lanka | Ethical manufacturing, quality focus | Mid-to-premium, conscious brands |

Factors to Consider When Choosing a Location

Knowing where t-shirts are manufactured is only half the battle. You also need to decide what matters most to your business model.

- Volume (MOQ): Are you making 50 shirts or 5,000? Offshore manufacturers (China/India) typically require higher Minimum Order Quantities (MOQs) but offer better unit prices.

- Lead Time: Australian manufacturing is faster (weeks), whereas offshore can take months for shipping.

- Fabric Customization: If you want custom fabrics (like a specific bamboo/cotton blend), offshore is usually the only viable option.

T-Shirt Manufacturing & Sourcing for Australian Businesses

While most t-shirts sold in Australia are imported, there is a small but growing local manufacturing sector focused on quality, ethical production, and quick turnaround. Many manufacturers in Australia offer a diverse range of styles, materials, and quality options to suit different needs. Local manufacturers often specialize in small batch production, providing flexibility for startups and brands seeking limited runs. They also offer customization services, such as personalized clothing options and custom T-shirts, to meet specific branding needs. One of the key benefits of working with Australian manufacturers is the personalized support they provide, ensuring smooth collaboration throughout the process. These manufacturers work closely with clients to deliver tailored solutions that align with their unique requirements.

Current State of Australian T-Shirt Manufacturing

- Limited Scale: High labor costs and competition from Asia mean most production happens offshore.

- Niche Focus: Local manufacturers specialize in small runs, custom designs, premium quality, and ethical production.

- Key Locations: Melbourne, Sydney, Brisbane have boutique textile and printing facilities.

Benefits of Australian-Made T-Shirts

- Quality Control: Direct oversight of production standards.

- Fast Turnaround: No lengthy shipping times.

- Support Local Economy: Keeps jobs and skills in Australia.

- Ethical Assurance: Adherence to Australian labor laws and workplace safety.

- Sustainability: Reduced carbon footprint from shorter supply chains.

Challenges

- Higher Costs: Australian-made t-shirts typically cost 2-5x more than imported equivalents.

- Limited Fabric Supply: Most raw materials and textiles still need to be imported.

When to Choose Local Australian Manufacturing

- Small custom orders (under 100 units)

- Premium or boutique brands emphasizing “Made in Australia”

- Urgent deadlines (1-2 weeks vs. 6-12 weeks from overseas)

- Brands prioritizing transparency and ethical production

How to Find a T Shirt Manufacturer: Import vs Local Sourcing

Why Most Australian Brands Import T-Shirts

Domestic Australian Manufacturing Reality:

- Labour cost: 20−20−30/hour (AUD)

- Typical production cost: 12−12−18 AUD per basic tee

- Retail price required: 40−40−60 (to achieve 50-60% margin)

- Challenges: Limited fabric mills, small production runs, high overheads

Option 1: Direct Import from Manufacturers (For Established Brands)

When Direct Import Makes Sense:

✅ Order volume: 2,000+ pieces per order (minimum)

✅ Budget: 10,000−10,000−20,000+ USD per order

✅ Capability: In-house QC, logistics, customs clearance knowledge

✅ Timeline: 60-90 days planning horizon (production + shipping)

Step-by-Step Direct Import Process:

Step 1: Find Manufacturers

- Alibaba.com: 50,000+ t-shirt manufacturers (filter by “Trade Assurance”, “Verified Supplier”)

- Global Sources: Premium B2B platform (higher-quality suppliers)

- Trade Shows:

- Canton Fair (China, April/October)

- Texworld (Various locations)

- Magic Trade Show (Las Vegas, but Asian exhibitors)

- Sourcing Agents: 5-10% commission but handle vetting, QC, logistics

Step 2: Vet Suppliers (Critical for Quality)

- ✅ Request factory audit reports (BSCI, WRAP, SA8000)

- ✅ Check certifications: OEKO-TEX (fabric safety), GOTS (organic), ISO9001 (quality management)

- ✅ Ask for client references (Australian brands if possible)

- ✅ Order pre-production samples (50−50−150, refundable on order)

- ✅ Test samples: Shrinkage (AATCC 135), colourfast (ISO 105), GSM weight

Step 3: Negotiate Terms

- MOQ: Negotiate down (offer multi-design orders to meet factory minimums)

- Payment terms:

- Standard: 30% deposit, 70% before shipment

- With Trade Assurance: Payment held by Alibaba until delivery confirmed

- Incoterms:

- FOB (Free On Board): You arrange shipping (more control)

- CIF (Cost, Insurance, Freight): Factory handles (easier but less control)

Step 4: Production & QC

- Pre-production sample: Approve exact fabric, colour, print before bulk

- During production inspection (DPI): At 30-50% completion (optional, 200−200−350 via SGS, Bureau Veritas)

- Pre-shipment inspection (PSI): Before leaving factory (essential, 250−250−400)

Step 5: Shipping to Australia

- Sea freight:

- China/Vietnam: 12-25 days to Sydney/Melbourne (1.20−1.20−2.00/kg)

- Bangladesh/India: 25-40 days (1.80−1.80−2.80/kg)

- Air freight: 5-8 days (but 8−8−15/kg, only for urgent orders)

- Freight forwarders: DHL Supply Chain, Kuehne+Nagel, or local specialists

Step 6: Customs Clearance

- Duty rates (2025):

- China: 10% (5% under ChAFTA for certain categories)

- Vietnam: 0-5% (AAVFTA preferential rates)

- Bangladesh/India: 10-17.5%

- GST: 10% of (CIF value + duty)

- Customs broker: 150−150−300/shipment (handles paperwork)

Total Timeline: 55-90 days (10 days sampling + 30-45 days production + 15-35 days shipping)

Option 2: Australian Wholesalers/Importers (For Small Businesses)

When to Buy from Australian Wholesalers:

✅ Lower volume: 50-500 pieces

✅ Faster turnaround: Stock available immediately (no 60-90 day wait)

✅ No import hassle: No customs, freight, MOQ stress

✅ Lower risk: See/touch product before buying

⚠️ Higher cost: 30-50% markup vs direct import

List of Australian T-Shirt Manufacturer

1. MAES(https://allactivewear.au/)

Company Profile: Professional activewear and functional sportswear manufacturer catering to brands, covering OEM/ODM, private label, and ready-to-ship catalogue products. MAES specializes in oem manufacturing, supporting clients from design to finished garments, and is committed to delivering high quality products. Emphasises specialist R&D teams, Australian size compatibility, low MOQs (moq varies depending on product and customization level), and sustainable fabric options. Established years ago, MAES has focused exclusively on Australia’s sportswear wholesale market, accumulating extensive industry experience and a robust client base. Our core business encompasses multiple categories including sports t-shirts, training wear, and team uniforms, primarily serving gyms, sporting clubs, corporate groups, and retailers.

Through our commitment to quality products and professional service, MAES has built an excellent reputation within Australia’s sportswear wholesale industry, becoming a trusted partner for numerous clients.

Main Products: High-performance activewear sets (leggings, sports bras), seamless collections, compression wear, functional tops, and comprehensive activewear ranges; also produces ready-to-ship blank/sample styles.

Advantages:

- Focuses on functional fabrics and activewear construction (seamless, compression, moisture-wicking, etc.), ideal for sports brands and e-commerce

- Offers sample development, AU size alignment, colour customisation, and private labelling services; MOQs friendly to new brands (starter programme available)

- Provides DDP delivery, compliant trade documentation, and fabric testing (colour fastness, UPF, chlorine resistance, etc.)

- Includes pattern making and tech packs as part of their comprehensive service to ensure design accuracy and efficient workflow

- Handles fabric sourcing, offering a wide range of materials including sustainable fabrics to meet client needs

- Efficient production process enables MAES to produce garments to high standards, delivering finished garments ready for market

- Delivers competitive prices and affordable prices, making high quality products accessible for clients

Disadvantages:

-

Certain fully customised projects require higher MOQs and longer lead times for quantities and colours (particularly custom-dyed or seamless knit items); moq varies depending on the product and level of customization

2. T-Shirt Magic(https://tshirtsapronsshoppingbags.com.au/)

Company Profile: Sydney-based t-shirt supplier and print shop with over 30 years’ history, integrating design, screen printing, embroidery, and direct-to-garment (DTG) digital printing. Supports small-batch orders with delivery across Australia and internationally.

Main Products: Men’s/women’s/children’s t-shirts (printed or plain), team/school/club apparel, tote bags, aprons, tea towels, and other promotional textiles. Offers custom designs and delivers finished garments ready for immediate use.

Advantages:

- Local factory with fast response times; flexible for samples and small quantities

- Multiple printing techniques available (screen printing, DTG digital printing, embroidery, heat transfer) suitable for diverse requirements, including vibrant, high-quality custom designs

- Extensive experience with well-equipped factory facilities

Disadvantages:

- Website information is fairly generic, lacking some technical specifications (fabric composition, detailed MOQ tables)

- Compared to specialist high-performance sportswear suppliers, products focus mainly on general/promotional categories with limited functional fabric options

3. The T-Shirt Co(https://thetshirtco.com.au/)

Company Profile: Brisbane-based custom and on-demand printing facility championing eco-friendly processes (Kornit/water-based NeoPigment inks, zero wastewater printing). Supports no minimum order quantities and express same-day dispatch (under specific conditions).

Main Products: On-demand personalised t-shirts (full-colour DTG), pre-designed merchandise, corporate/event print collections.

Advantages:

- Emphasises sustainability and environmental responsibility (low water usage, low energy consumption, non-toxic water-based inks); brand-friendly for eco-conscious businesses

- No minimum order requirements (suitable for single-item or small orders); strong rapid delivery capability

- Local production; supportive of small brands/e-commerce, enabling on-demand production to reduce inventory waste

Disadvantages:

- Primarily DTG and on-demand printing; for large-volume single-colour screen printing, traditional screen printing may offer the lowest cost per unit

- If requiring bulk orders or functional fabrics (compression/high-performance materials), supply chain support needs confirmation

4. MyTees(https://www.mytees.com.au/)

Company Profile: Sydney-based custom and corporate/promotional apparel supplier positioning itself as a customisation specialist for businesses, tradies, events, and industrial wear, offering multiple printing and embroidery techniques.

Main Products: Corporate/company/promotional t-shirts, polos, hoodies, workwear, printing and embroidery services.

Advantages:

- Targets corporate and bulk promotional markets with diverse printing/embroidery capabilities

- Claims extensive experience handling large orders and multiple styles; suitable for clients requiring bulk corporate purchases

- Provides design assistance and online customisation tools with low barriers to entry

Disadvantages:

- Website copy is promotional and market-oriented, with limited technical details (fabric specifications, technical limitations of available processes, capacity data)

- For those seeking eco-friendly or specialist sports fabrics, raw material sourcing and performance data require separate confirmation

- Details about raw materials sourcing and fabric composition may require direct enquiry

5. OCC Apparel(https://occapparel.com.au/)

Company Profile: Wholesale and manufacturer specialising in organic, sustainable, and fair-trade certified apparel. OCC Apparel is a leading clothing manufacturer trusted by both startups and established brands. Offers local and international manufacturing with multiple ethical/environmental certifications (such as GOTS, Fairtrade, Fair Wear, etc.).

Main Products: Organic cotton t-shirts, eco-friendly/fair-trade clothing, custom printing and embroidery services, relabelling, professional mockups, and brand packaging services.

Advantages:

- Strong sustainability and ethical credentials; ideal for brands pursuing environmental certifications and supply chain transparency

- Comprehensive garment decoration options (screen printing, embroidery, heat transfer) and value-added services (labelling, mockups)

- Can provide certification documentation, beneficial for sustainable brand marketing and corporate compliance

Disadvantages:

- Organic/certified fabric costs typically exceed conventional fabrics; price-sensitive buyers need to weigh trade-offs

- If requiring very rapid delivery or extremely low MOQs, certified product supply chain timelines may be less flexible than standard short runs

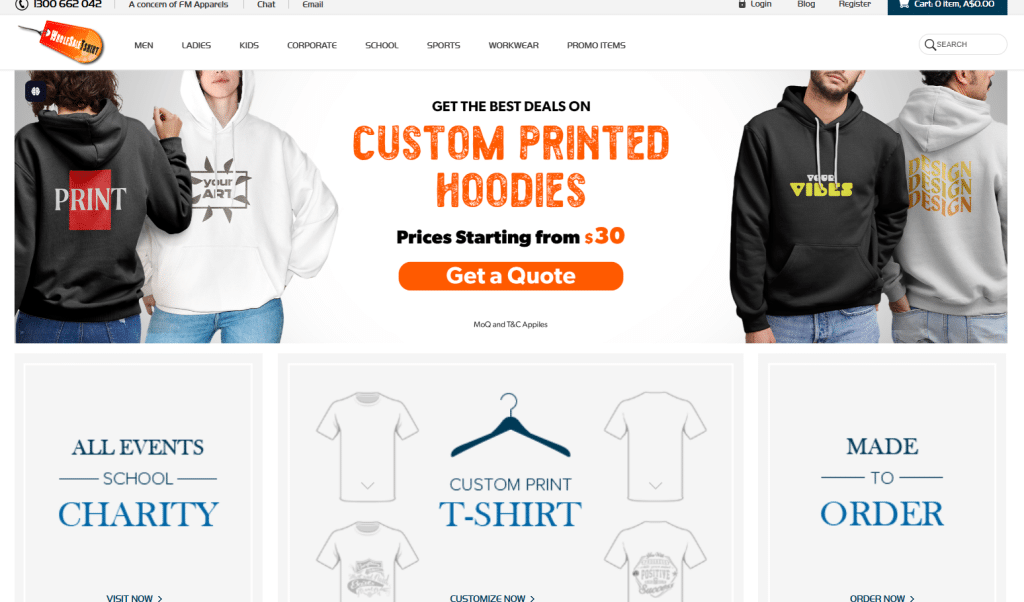

6. WholesaleTShirt(https://wholesaletshirt.com.au/)

Company Profile: Major Australian wholesale supplier of blank t-shirts and promotional apparel, emphasising bulk quantities, competitive pricing, and extensive brand and basic style inventory. Recognised among Australia’s top clothing manufacturers, WholesaleTShirt serves clients including charities, gyms, schools, and large-scale events.

Main Products: Wholesale blank t-shirts, polo shirts, hoodies, caps, and customisable promotional merchandise, plus stock from multiple brands.

Advantages:

- Large inventory and low-price strategy; suitable for clients requiring substantial basic styles or promotional materials

- Supports online ordering and streamlined procurement processes; broad client base spanning institutions and events

- Wide selection of brands and styles enabling one-stop purchasing of basic apparel

Disadvantages:

- Primarily blank/standard styles; limited options for premium fabrics or complex technical customisation (seamless/high-stretch fabrics/functional treatments)

- Quality and environmental attributes vary by brand and specific style; requires item-by-item verification

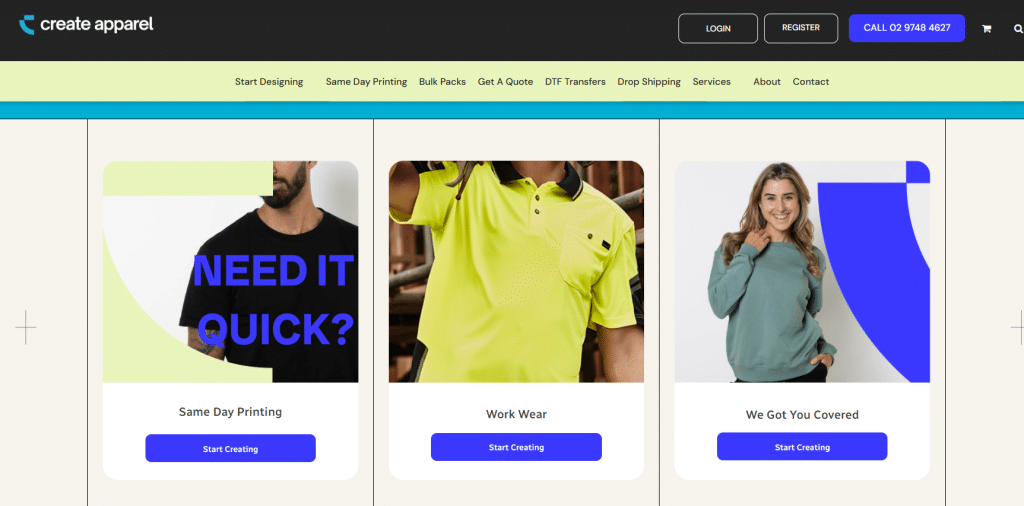

7. Create Apparel(https://www.createapparel.com.au/)

Company Profile: Australian-based custom clothing manufacturer and on-demand custom and printing service provider offering custom t-shirt printing, design support, and per-item production. Website emphasises local production, user-friendly online ordering and design workflow, and on-demand supply capability for SMEs and e-commerce.

Main Products: Custom printed t-shirts, single-item or small-batch DTG printing, team/event t-shirts, promotional items, and pre-designed merchandise.

Advantages:

- Convenient online design and ordering process; suitable for e-commerce and small-batch clients

- Local printing with fast turnaround; ideal for urgent and express requirements

- On-demand/no-inventory model reduces stock costs and waste

Disadvantages:

- For large-volume, single-colour screen printing, suppliers with traditional screen printing may offer better unit cost advantages

- Website content relatively brief; technical parameters (fabric specifications, certifications) may require additional quotation enquiries

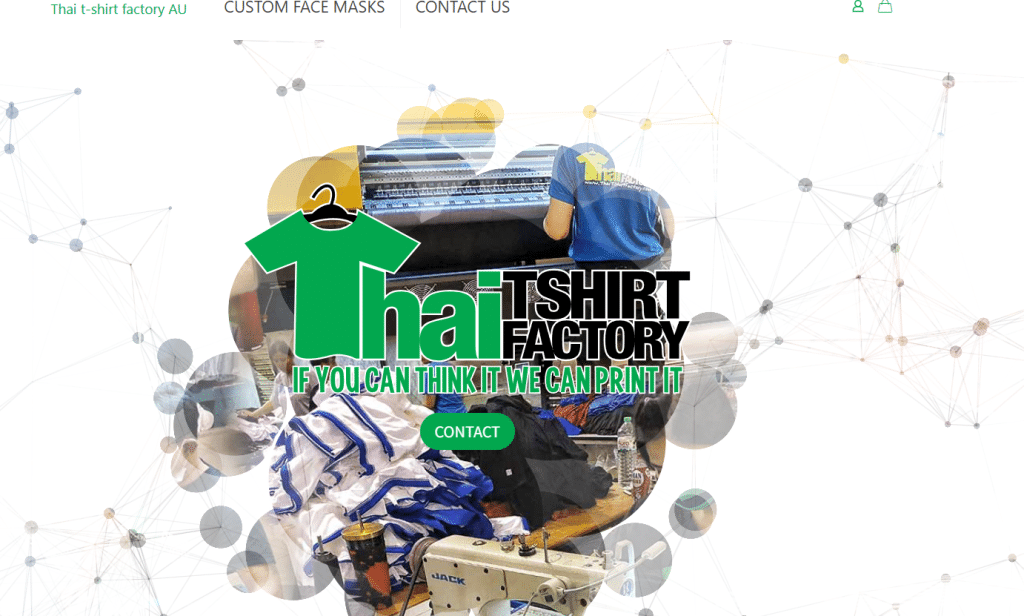

8. Thai T-Shirt Factory(https://thaitshirtfactory.com.au/)

Company Profile: Full-service apparel manufacturing and printing provider with production base in Thailand, serving the Australian market. Thai T-Shirt Factory is positioned among the top t shirt manufacturers catering to Australian brands, offering reliable quality and flexible solutions. Operating since 2007 with multiple international brand partnerships, offering complete OEM capability from design and sampling through to bulk production. Accepts low minimum orders (from approximately 30 pieces) with DHL global shipping options. Zega Apparel is another example of a leading t-shirt manufacturer specializing in custom apparel, known for ethical production and comprehensive in-house services.

Main Products: T-shirts, polos, hoodies, sportswear, workwear, swimwear (bikinis), caps, embroidery/patches, boxing gear, and other private label and custom products.

Advantages:

- Large and diverse production capacity; capable of cut-and-sew, sublimation, screen printing, embroidery, and other techniques

- Low minimum orders (suitable for small brand start-ups, e.g., 30 pieces minimum); new-brand friendly

- Provides end-to-end service from design support through to packaging and labelling; claims partnerships with multiple well-known brands

- Offers fast-dispatch stock blank items and discounted parcel options (including international tracking)

Disadvantages:

- Actual production in Thailand may involve international shipping time and customs duties (requiring consideration of clearance and taxes)

- Some buyers prefer fully local production to shorten delivery times and support “Made in Australia” domestic branding

- Quality and compliance (such as social responsibility, factory certifications) require buyers to verify specific certificates and factory audit records before ordering

Option 3: Hybrid Model (Best of Both Worlds)

Strategy:

- Start with wholesalers (test market, low risk)

- Validate designs (which styles/colours sell best?)

- Scale with direct import (once monthly sales >200 units/design)

Example:

Month 1-6: Buy 50-100 pieces/month from AS Colour (10AUD),sellat10AUD),sellat35 = 72% margin

Month 7+: Switch to direct import (1,000 pieces Vietnam, 4.50AUDlanded),sellat4.50AUDlanded),sellat32 (competitive pricing) = 86% margin + volume

Benefits of Working with Australian Manufacturers

Partnering with Australian manufacturers offers a range of advantages for businesses seeking to produce high quality t shirts with a focus on sustainable production and ethical standards. Australian t shirt manufacturers are known for their commitment to ethical production, using premium materials such as organic cotton and recycled fabrics, and upholding strict ethical labor practices. Ethical production includes fair wages and safe working conditions for garment workers. Many are certified by organizations like Ethical Clothing Australia, and can provide GOTS certified organic cotton, ensuring that every custom t shirt meets rigorous environmental and social criteria.

Australian manufacturers also offer flexibility in production techniques and order sizes, making them an excellent choice for small businesses and startups that require low minimum order quantities and tailored solutions. Their expertise in fabric selection, custom t shirt design, and advanced production methods ensures that the finished product consistently meets or exceeds expectations. Additionally, working with local manufacturers simplifies compliance with Australian regulations and international standards, providing peace of mind for brands focused on quality and sustainability.

By choosing an Australian manufacturer, businesses gain a competitive edge in the global t shirt market, benefit from responsive service, and contribute to the growth of ethical clothing in Australia. This partnership not only results in superior t shirts but also supports sustainable and responsible practices throughout the supply chain.

Future Trends in T-Shirt Manufacturing (2025-2030)

Trend 1: Nearshoring & Regionalization

Impact on Australia:

- Vietnam rising: Already 12-18 day shipping (vs 25-35 Bangladesh)

- Indonesia potential: ASEAN integration, growing capacity

- Pacific Islands: Fiji, PNG exploring garment manufacturing (Australian aid programs)

Prediction: Vietnam to capture 18-20% global share by 2028 (from 12% in 2024)

Trend 2: Automation & Smart Factories

What’s Changing:

- Automated cutting: Laser/water-jet cutters (±0.5mm precision vs ±3mm manual)

- Sewbots: Robotic sewing (1 shirt/80 seconds vs 10 minutes manual)

- AI quality control: Computer vision detecting defects (99% accuracy)

Where: China leading (60% of factories have partial automation), Vietnam following

Impact on Pricing: Automation reducing costs 15-25% by 2027 (offsetting wage increases)

Trend 3: Sustainable Materials Innovation

Emerging Fabrics:

- Recycled polyester (rPET from ocean plastics): 30% cheaper than virgin polyester by 2026

- Tencel/Lyocell (eucalyptus-based, biodegradable): Growing from 2% to 8% market share

- Hemp blends (carbon-negative, durable): Pilot production in China/India

- Lab-grown cotton (MycoWorks, Bolt Threads): Commercial by 2028-2030

Australian Opportunity: Early adopter brands can differentiate (68% consumer willingness to try new sustainable materials)

Trend 4: On-Demand Manufacturing (Small Batches)

What It Means:

- MOQ dropping: Turkey/Portugal offering 50-100 piece runs

- Print-on-demand integration: Alibaba, Printful expanding in Asia

- 3D knitting: Whole-garment machines (zero waste, custom fit)

Best For:

- Boutique Australian brands (test designs without 1,000-piece commitment)

- Influencer collaborations (limited drops, 100-300 pieces)

- Custom corporate (logo tees, 50-200 quantity)

Conclusion: Choosing the Right Manufacturing Strategy for Your Australian Brand

To get the most out of sourcing, stay informed about where are most t shirts manufactured and always vet suppliers thoroughly.

The global t-shirt manufacturing industry presents a diversified development landscape, with Asian countries maintaining dominance through cost and scale advantages, whilst Australian domestic manufacturers hold unique strengths in quality control, rapid response, and sustainable development. Choosing the right t-shirt manufacturer requires comprehensive consideration of multiple factors including product quality, pricing, delivery capability, and service standards.

As Australia’s leading activewear wholesale specialist, MAES leverages years of industry experience, robust supply chain networks, stringent quality control systems, and comprehensive customer service to provide Australian businesses and organisations with premium t-shirt wholesale services. We’re not just your supplier – we’re your reliable partner in business growth.